Why Donald Trump‘s Metal Tariffs Won’t Lead to the All-American iPhone

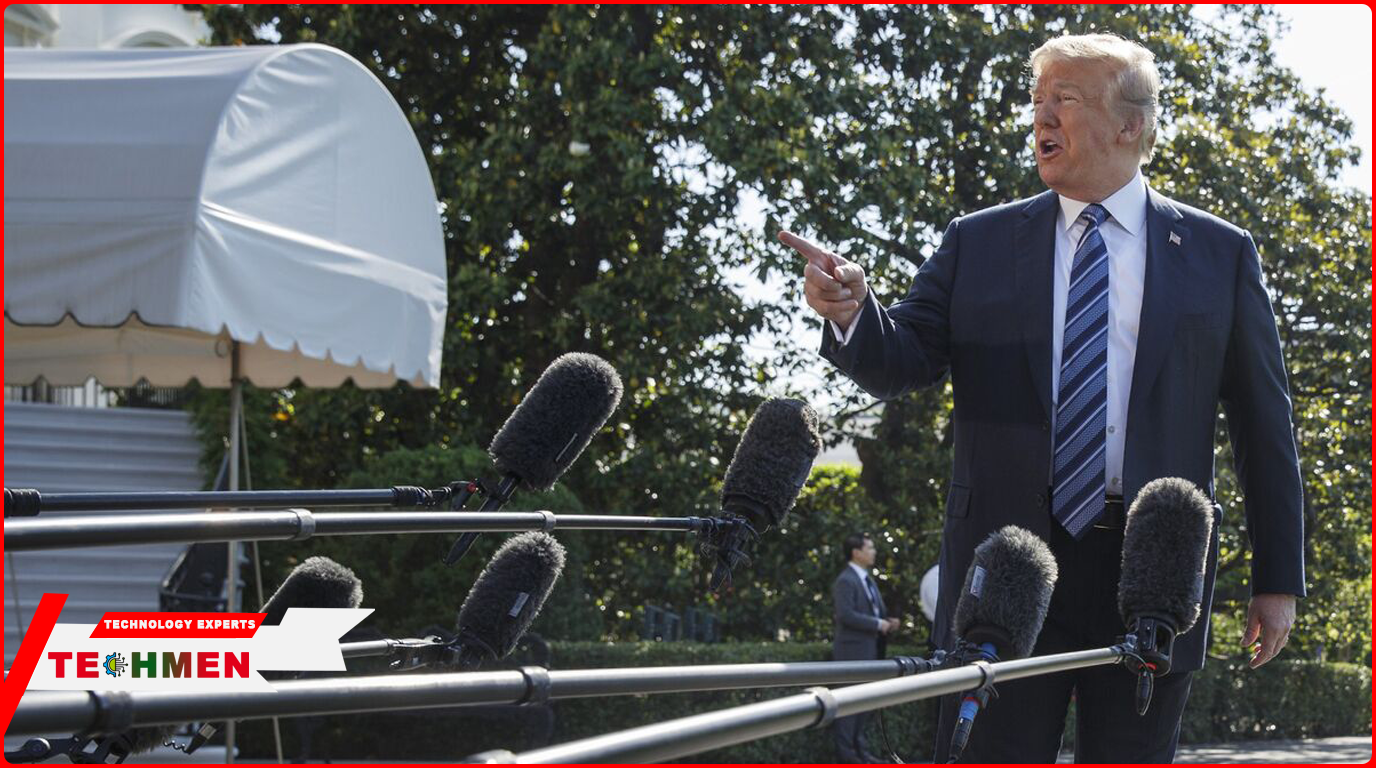

The iconic iPhone, which has become synonymous with sleek design and innovation, is a product of global collaboration. But when former President Donald Trump’s administration slapped hefty tariffs on imported metals—especially aluminum and steel—it was assumed that American manufacturers would somehow rediscover their competitive edge and revive the glory days of American-made tech. But here’s the truth: those metal tariffs won’t bring back the “All-American iPhone” anytime soon. In fact, the tariffs may have the opposite effect, making it more expensive and less practical for Apple to manufacture in the U.S. Let’s break down why.

The Tariff Dream: An Overblown Fantasy

In 2018, Trump’s administration imposed tariffs of up to 25% on imported steel and 10% on aluminum in an effort to protect American industries from foreign competition. The move was designed to boost domestic production, create jobs, and reduce America’s reliance on foreign imports. But Trump’s vision of a return to America’s industrial manufacturing glory days didn’t quite align with the reality of global supply chains in today’s world.

Apple’s iPhone, the company’s flagship product, is the result of a finely tuned global supply chain. Its design, development, and manufacturing rely on components from various countries—China, South Korea, Japan, and beyond. Apple sources materials like rare-earth metals, silicon, and steel from all over the world. For Apple, moving manufacturing to the U.S. would require far more than a simple shift in tariffs or a patriotic appeal.

The Reality of Apple’s Global Supply Chain

Apple’s iPhone is not just an American product; it’s a testament to globalization. The device’s production process spans continents. The company designs the iPhone in Cupertino, California, but the majority of its assembly takes place in China, with key components coming from places like South Korea and Japan.

For example, the iPhone’s aluminum casing, one of its most recognizable features, is primarily sourced from outside the U.S. Companies like Taiwan’s Foxconn (which manufactures iPhones) and South Korea’s LG and Samsung produce essential components. The metals used in these parts, such as aluminum and rare earth minerals, are sourced from global suppliers, not U.S.-based mines or refineries.

Trump’s tariffs hit these key materials hard. By raising the price of imported metals, the administration inadvertently raised the cost of the components used to make the iPhone. The impact was particularly notable for Apple, whose production model relies on keeping costs down to maintain the slim profit margins required for a $1,000+ retail price. When the price of metals like steel and aluminum went up, Apple was forced to consider alternative suppliers, but even then, the choices were limited. Moving production to the U.S. to avoid these tariffs would not only disrupt the established supply chain but also raise labor and manufacturing costs significantly.

The Costs of ‘Made in the USA’

So, let’s imagine the scenario where Apple does decide to build an “All-American iPhone.” To avoid the tariffs on imported metals, they would need to source materials from within the U.S. But let’s not be naive: there are several hurdles standing in the way.

First, the United States doesn’t have the capacity to meet Apple’s metal demands on the scale needed. Even though the U.S. produces aluminum and steel, it’s not at the scale required for mass tech manufacturing. The industry simply doesn’t have the infrastructure, workforce, or capacity to supply Apple’s needs at the prices they’ve been accustomed to. Setting up new foundries or metal-processing plants in the U.S. would take years and billions of dollars in investment. And let’s not forget, metal prices are only one piece of the puzzle—iPhones require a vast array of materials, from chips to glass to plastics, many of which are sourced from abroad.

Second, there’s the labor cost. Manufacturing in the U.S. is far more expensive than in countries like China or India. The U.S. workforce is highly skilled, but also expensive. Even if the U.S. had the required manufacturing infrastructure, the cost of labor would skyrocket, pushing the price of the iPhone beyond the reach of most consumers. Apple might consider automating some of the processes, but automation alone wouldn’t overcome the fundamental cost discrepancies between U.S. labor and labor in countries like China.

Then, there’s the issue of environmental regulations. U.S. manufacturing is subject to stricter environmental standards than many other countries, meaning that if Apple were to set up shop in the U.S., they’d be forced to follow a much more rigorous set of rules on waste disposal, emissions, and resource management. These regulations would drive up production costs even further.

Globalization is Here to Stay

The simple truth is, globalization isn’t going anywhere. Apple has thrived by leveraging a global supply chain that minimizes costs and maximizes efficiency. Moving manufacturing to the U.S. would not only be an expensive and disruptive process but also an impractical one. Apple is unlikely to risk its position as a leader in the tech market by sacrificing its ability to produce products at competitive prices. The global supply chain, despite its challenges, remains the most efficient way to produce the iPhone.

In fact, the very idea of an “All-American iPhone” misses the point of what modern tech manufacturing is about. Companies like Apple are less interested in the national origins of the materials they use and more focused on their ability to innovate, keep costs low, and deliver high-quality products to consumers. The idea of a return to full U.S. manufacturing for high-tech products ignores the complex reality of the global supply chain that powers modern tech.

The Bottom Line

While Trump’s metal tariffs may have been a symbolic attempt to “bring back jobs” to the U.S., the notion that these tariffs could lead to an all-American iPhone is a fantasy. Apple’s manufacturing strategy is far more nuanced and dependent on the global supply chain than any simplistic “America First” policy could accommodate. The reality is, tariffs raise costs and complicate relationships with foreign suppliers, leading to higher prices for consumers, not a surge in American manufacturing.

To build the iPhone entirely in the U.S. would require far more than just slapping tariffs on steel and aluminum. It would take a massive overhaul of Apple’s production infrastructure, billions of dollars in new investments, and a willingness to face the challenges of labor costs, environmental regulations, and supply chain complexity. Until those changes occur, expect your iPhone to remain as international as it always has been—a product of a globalized world, rather than an “All-American” dream.